Company Structure Overview

Areas and Infrastructure

Surface Areas

- Indoor surface: 4,000 m2

- Outdoor driveway area: 11,000 m2

The indoor spaces house the structural steelwork, mechanical machining, and warehouse departments; the outdoor driveway area is suitable for heavy vehicle movement, loading/unloading operations, and temporary storage of components and scaffolding.

Lifting and Handling Capacity

- 4 overhead cranes (10 t each)

- 1 mobile crane (20 t)

- 1 mobile crane (10 t)

- 3.5 t forklifts

- Various minor equipment for handling and positioning

Lifting resources allow for the safe management of heavy and bulky loads within the plants and for loading operations onto road transport vehicles. Lifting procedures and equipment are subject to scheduled maintenance and periodic inspections.

Structural Steelwork Equipment

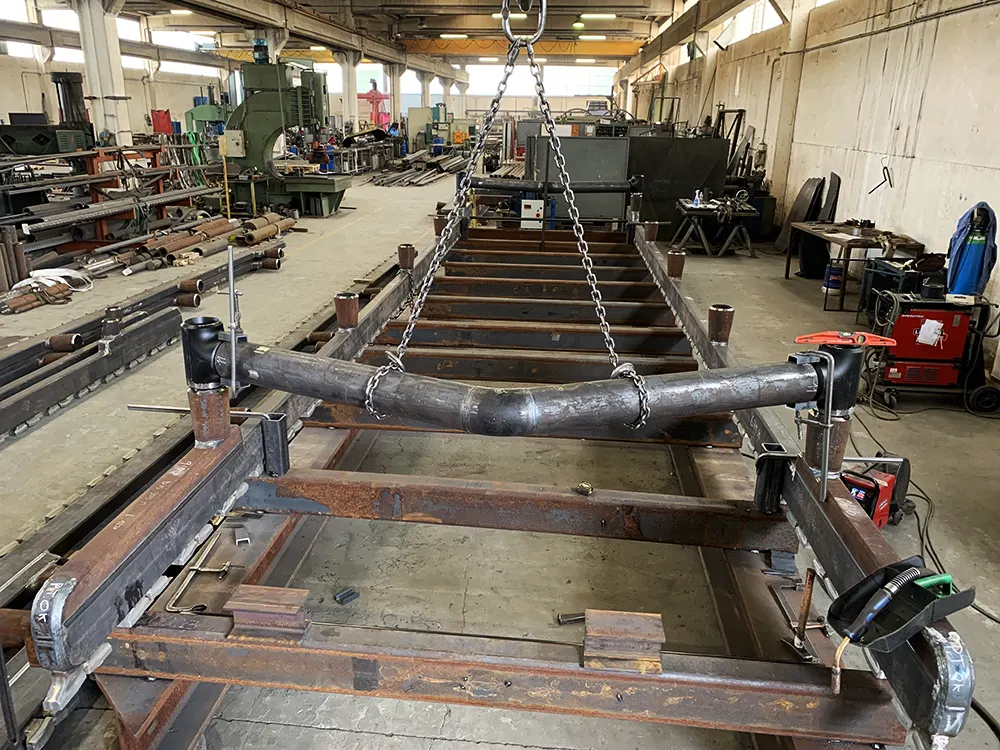

Workstations and Benches

Levelled and modular workbenches, with a total length exceeding 30 m, designed for large-scale assemblies and levelling and installation operations.

Machinery and Forming Processes

- CNC sheet metal forming machines

- Rolling machines for pipes and plates

- Press brake, shear, and various presses for cutting and bending operations

- CNC HD Plasma Cutting (chamber dimensions: 2,500 × 12,000 mm)

Lifting resources allow for the safe management of heavy and bulky loads within the plants and for loading operations onto road transport vehicles. Lifting procedures and equipment are subject to scheduled maintenance and periodic inspections.

Welding

Synergic welding machines for MAG/MIG/TIG processes, with qualified personnel and certified welding procedures. The use of synergic welding machines allows for easy parameter setting and repeatability of results.

- Submerged Arc Welding (SAW) plant

- Robotic plant with UR 10e Cobot

Checks and Calibrations

All instrumentation used for inspections is subject to periodic calibration based on certified samples and/or by qualified external bodies.

Process Controls

To ensure product quality at all stages, internal inspectors perform specific checks and tests according to defined QCPs:

NDT Weld Inspection

- Ultrasonic Testing (UT) with the possibility of remote inspection

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

- Visual/Dimensional Testing (VT)

Performed by qualified internal personnel (Level 2) with reporting and data storage according to company procedures.

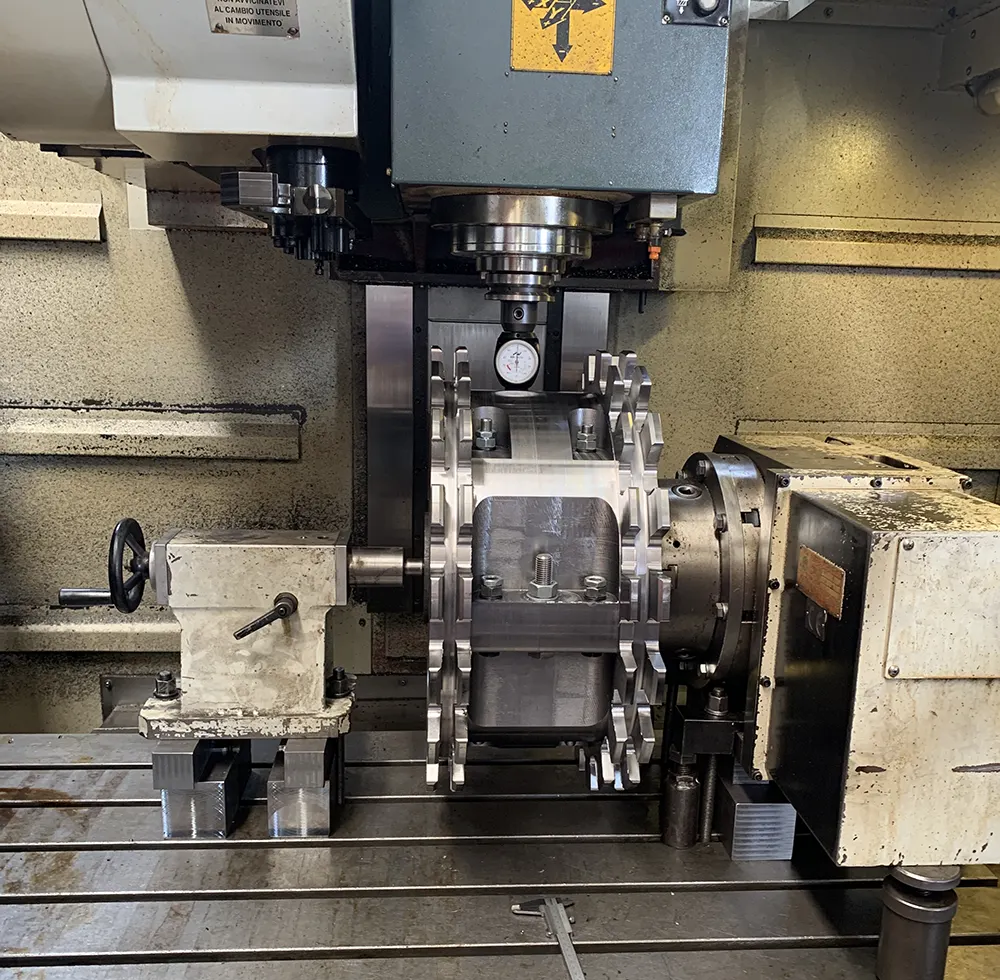

Mechanical Machining

- CNC lathes with useful travel up to 5 m (L = 5 m) for large-scale components

- CNC machining and drilling centers for precision work

- "Mecof" 10 m traveling column milling machine

- Other machinery